Multi-station bolt/nut/part formers

CBF/CBP/CNF/CNP

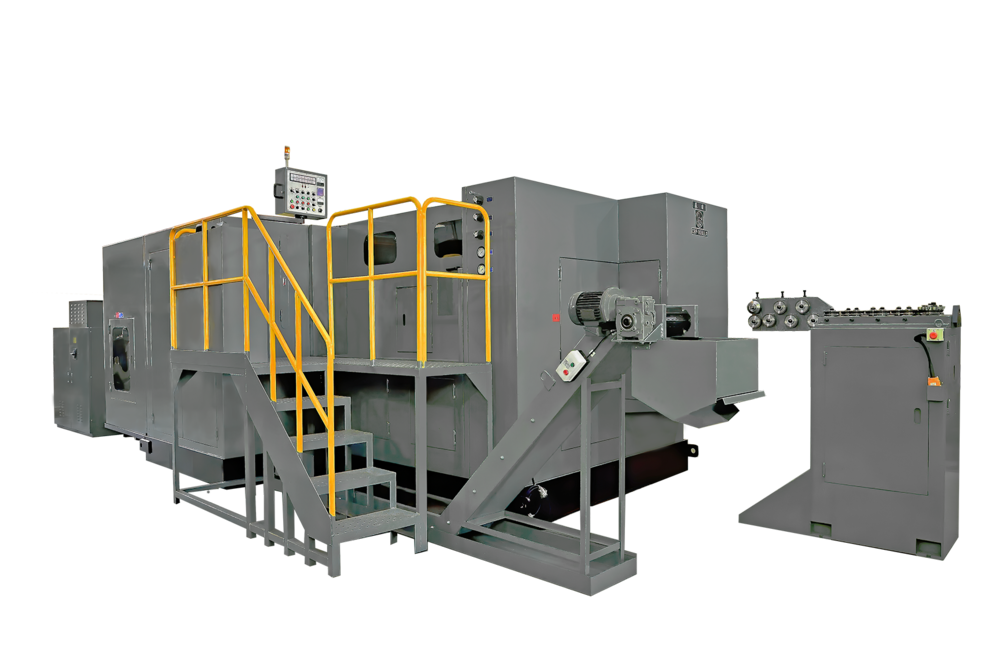

Chun Zu cold formers have been continuously improved over four decades of research and development. Along with the growth of Taiwan ’s fastener industry, it has developed the most comprehensive lineup on the market. We have shipped more than 10,000 units of machines worldwide in more than 50 countries with thousands of customers' satisfaction. Chun Zu machines are the best choice for your business!

- The air clutch brake system has been designed to actuate as “Inching ”, “Single stroke” and “Continuous running”. The main ram will always stop at rear position while operating either “Single stroke” or “Continuous running” cycle. (Except for CDH model)

- The main machine parts like frame or main ram has been normalized to release the internal stress after casting. It means to avoid deformation in the future and keeps its precision forever. This machine is made of gray cast iron, which has better rigidity and extremely low elongation to provide the machine with great stability.

- The stability and precision of the main slider is secured by “Overarm” design. The application of harden alloy steel plates fixed to it will help maintain its precision for a long periods of operation.

- Pneumatic gripper mechanism is adapted to obtain stable gripping function at high speed production. The gripping force can be adjusted according to each kind of product.

- CBP/CNP models adopt separate design for each station to install bolt type, nut type or combo type cassette gripper according to product requirements.

- The CBF/CBP/CNP series (M10 and above) are equipped with a dual lubrication system as standard. The crankshaft and main slider have an independent lubrication system, which is separated from other mechanisms.

- The counterweight of the mechanism design contributes to machine’s great stability.

- An inverter is installed on AC motor to allow variable speed during testing and production.

- CBF/CBP/CNP series are equipped with coolant supply pipe that automatically rises the device is standard for an easy operation.

|

ITEM |

CBF series |

CBP series |

CNF series |

CNP series |

| MACHINES |

BOLT FORMERS |

BOLT PARTS FORMERS |

NUT FORMERS |

NUT PARTS FORMERS |

|

NO. OF FORGING STATION |

3-4 |

5-8 |

5 |

5-7 |

|

MAX.FORGING LOAD (Ton) |

430 |

730 |

400 |

1000 |

| CUT-OFF DIAMETER (mm) |

∅2-∅30 |

∅2-∅41 |

∅5-∅32 |

∅5-∅48 |

|

CUT-OFF LENGTH (mm) |

10-320 |

10-450 |

3-35 |

20-180 |

| INTEGRATED TRANSFER SYSTEM |

○ |

|

○ |

|

|

CASSETTE TRANSFER SYSTEM (UNIVERSAL/STRAIGHT/COMBO)

|

|

○ |

|

○ |

|

TRIMMING MECHANISM |

○ |

○ |

|

|

|

PNUEMATIC CLUTCH |

○ |

○ |

○ |

○ |

|

|

|

| operation panel |

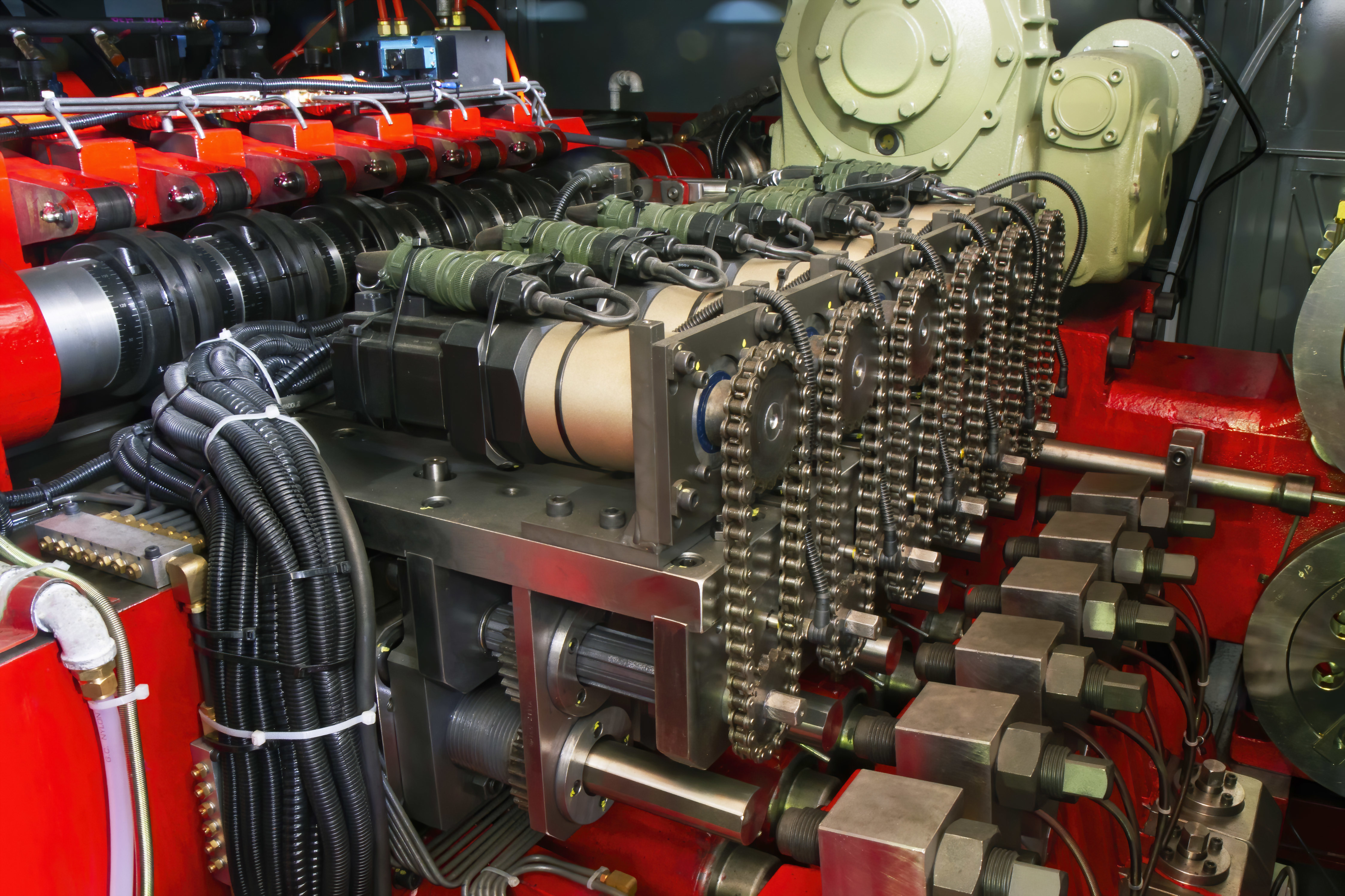

Dual Lubrication Pumps |

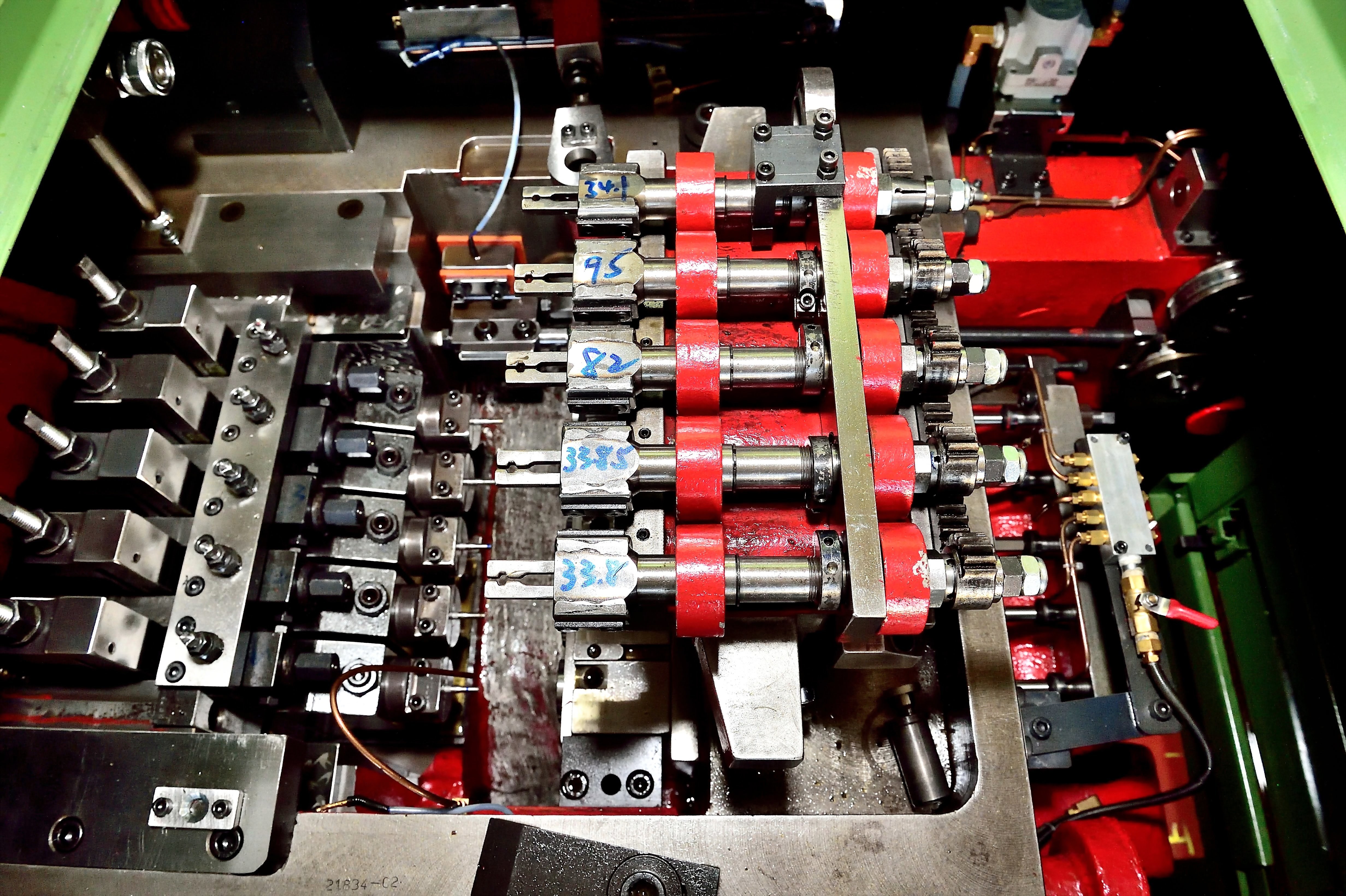

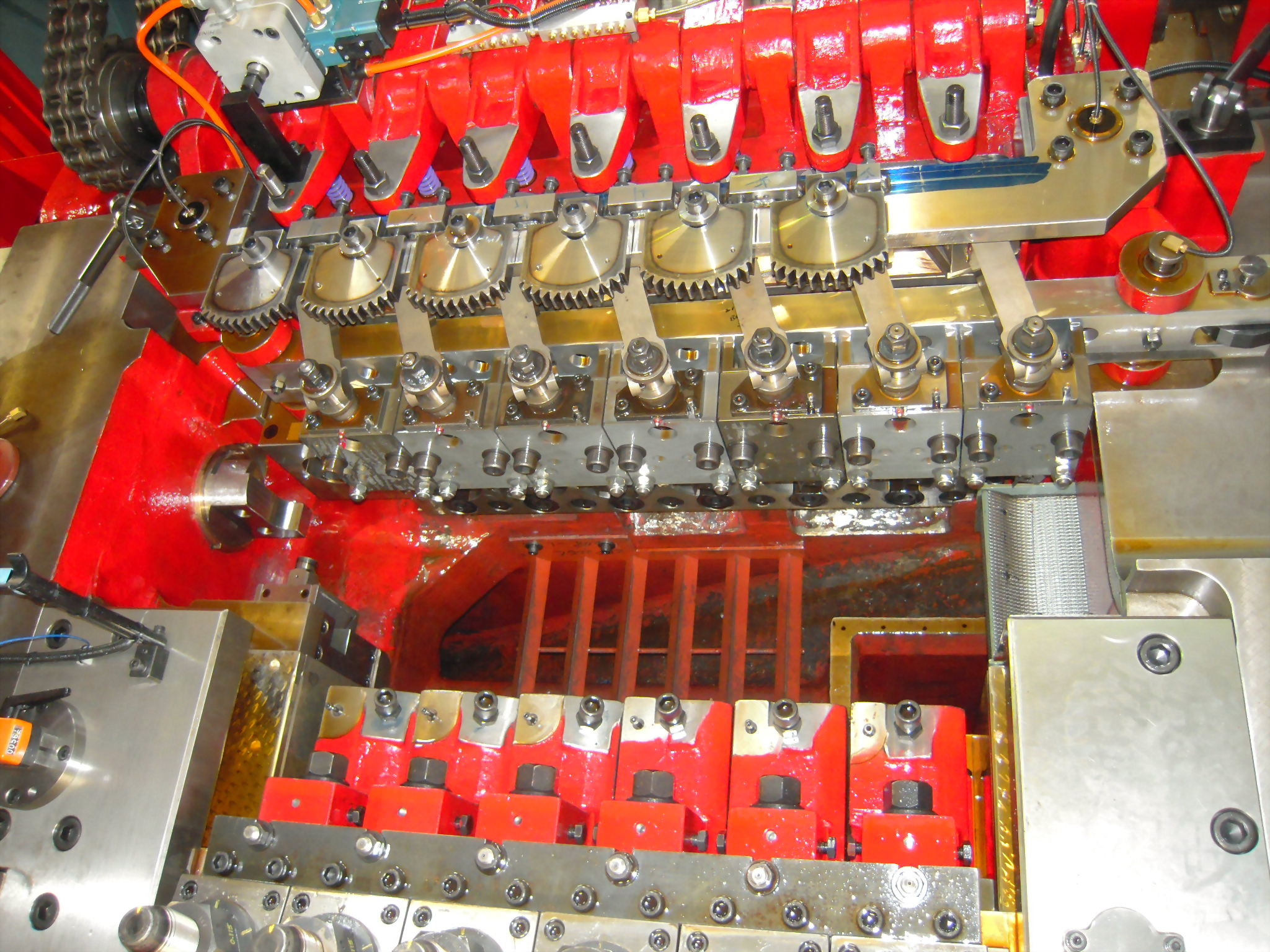

Forging technology |

|

|

|

|

Independent K.O. mechanism |

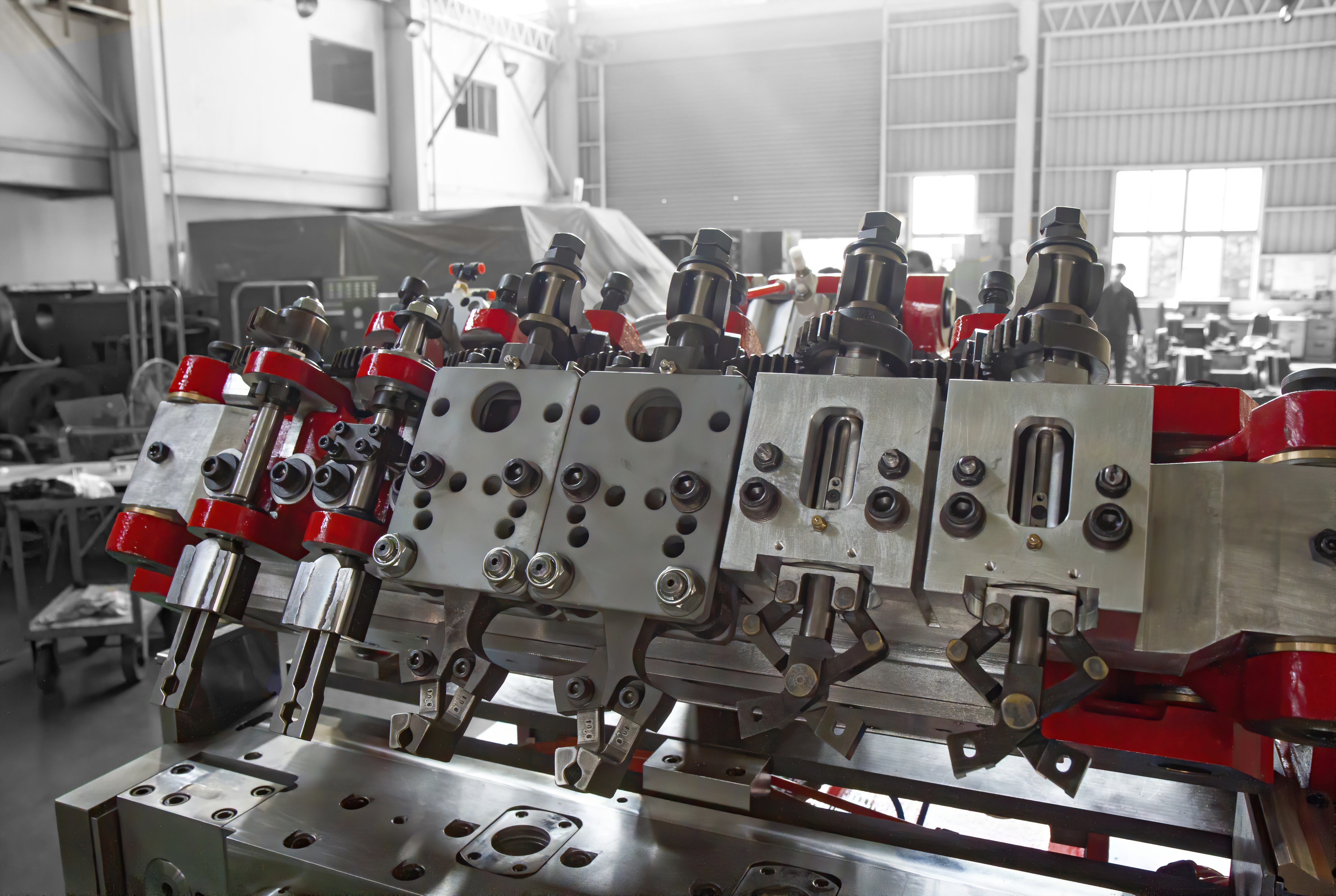

Cassette transfer system |

Cassette transfer system (Left to Right)A: universal transfer cassette B: straight transfer cassette C: combo type transfer cassette) |

|

|

|

|

Integrated transfer system(CNF series) |

Finished product anti-collision system (with extra finger to avoid parts damaged) |

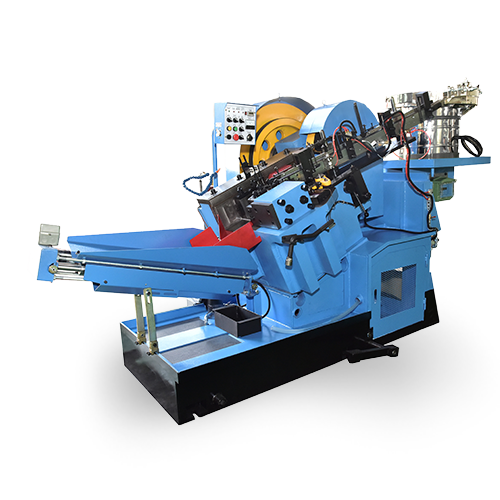

Feeding mechanism |

|

|

|

|

Feeding length adjustment (by servo motor) |

K.O. length adjustment (by hand wheel) |

K.O. length adjustment (by servo motor) |

|

|

|

|

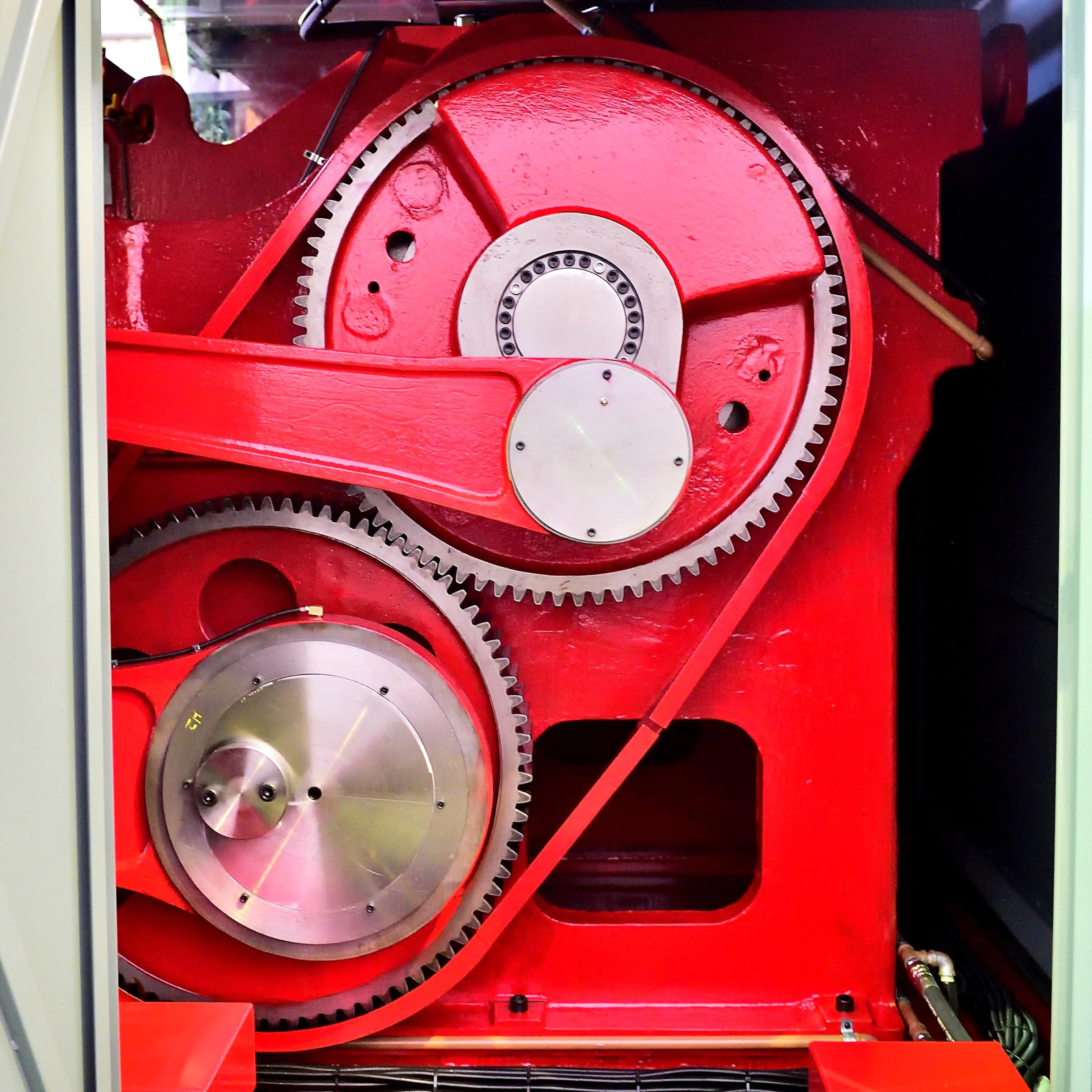

Transmission gear |

|

|