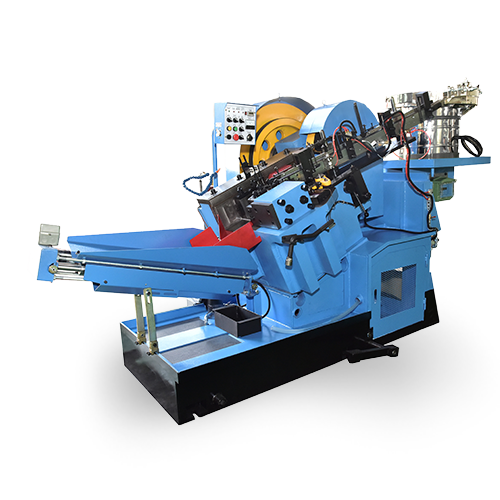

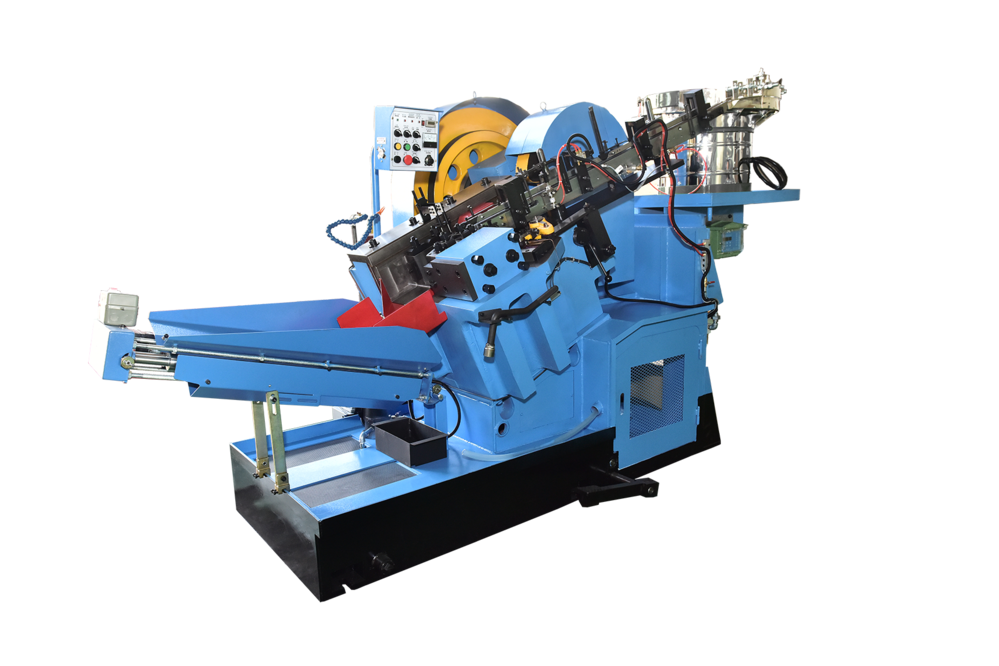

CPR Thread rolling machine

CPR

CPR series are thread rollers, developed by Chun Zu, with high speed and stability, and provides various detection and customization options.

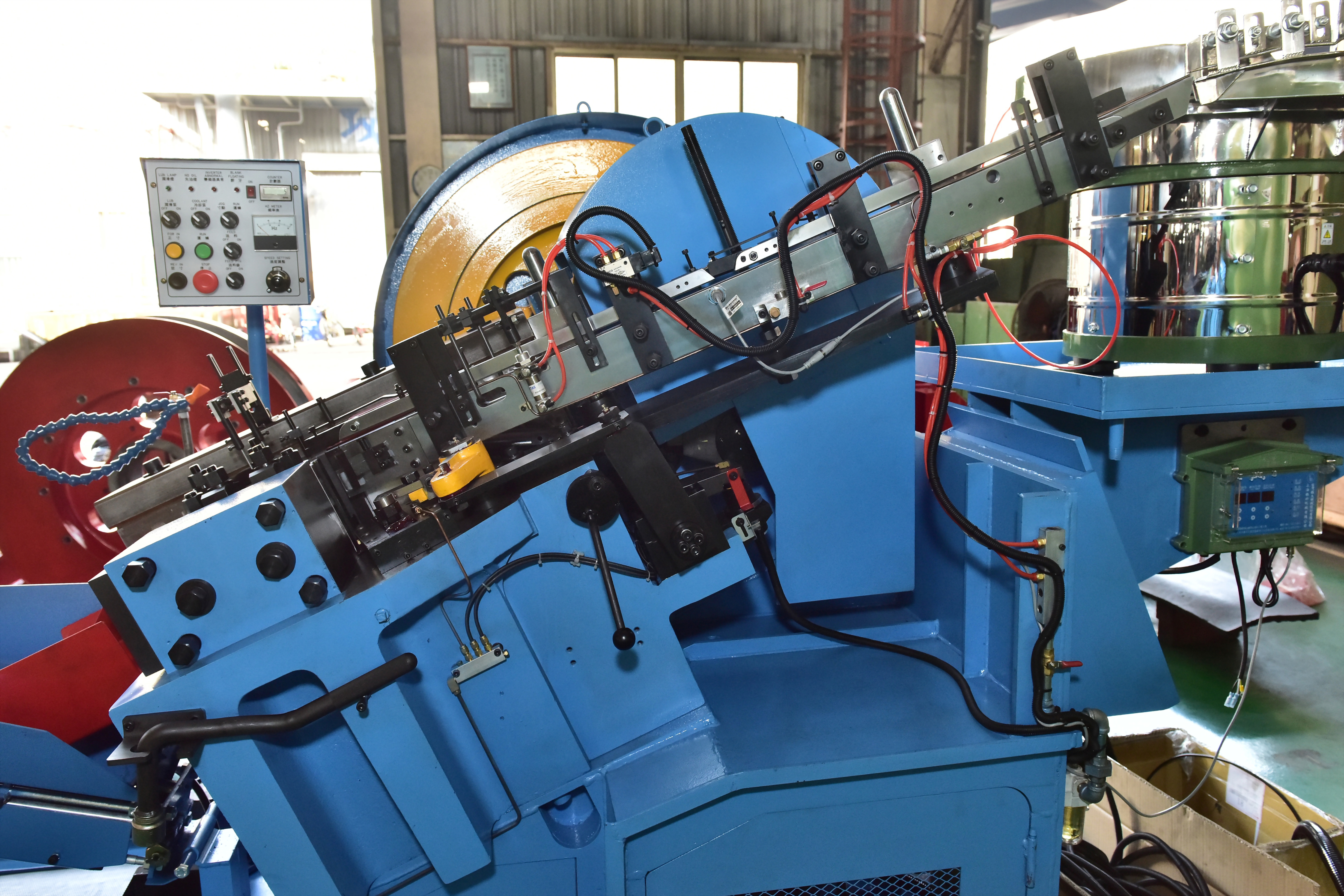

- A.C. motor and inverter are standard, which allow variable speed adjustment during jogging and continuous running.

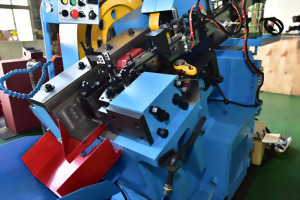

- Phosphoric bronze liners and hardened alloy steel liners are used for the sliding surface of the main slider to maintain high precision of threading and longer working life of thread dies.

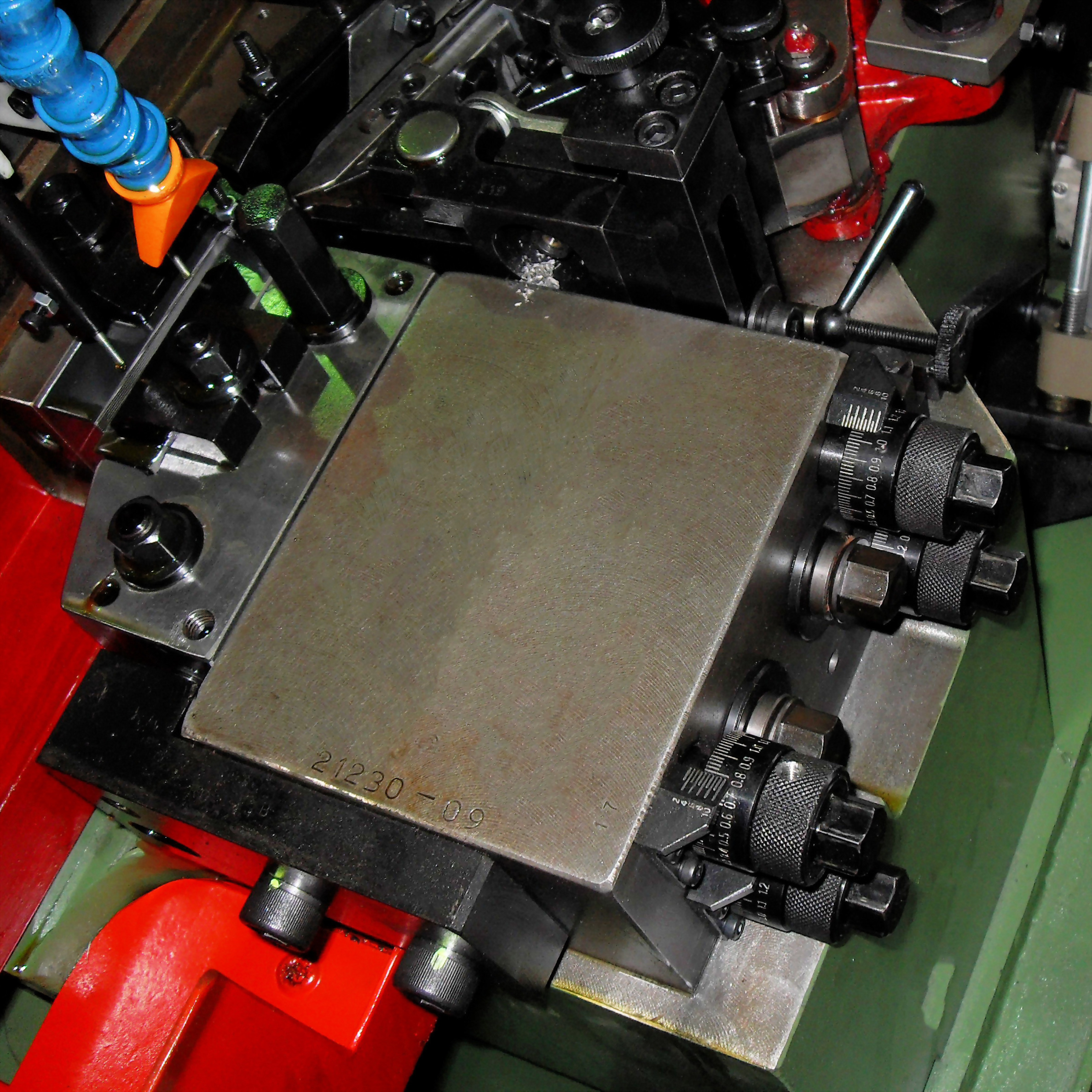

- 3 direction (X,Y,Z) adjustment of stationary die pocket makes the alignment of height and parallelism between stationary and moving die much easier.

- The main machine parts like frame or main slider has been normalized to release the internal stress after casting to avoid deformation in the future and keep precision forever. The machine is made of gray cast iron, which has better rigidity and extremely low elongation to provide the machine with great stability.

- This frame is designed and manufactured for high strength. The deformation of the frame is very small while rolling.

- Each mechanism can be easily adjusting according to different products.

| ITEM | CPR |

|

MACHINES |

Thread rolling machines |

| MIN.&MAX. THREAD DIAMETER mm | 2-42 |

|

MIN.&MAX. THREAD DIAMETER FOR SELF TAPPING SCREW mm (CPR3-CPR10) |

#2-#14 |

| MIN.&MAX. THREAD LENGTH mm | 3-250 |

| MIN.&MAX. SHANK LENGTH UNDER HEAD mm | 3-350 |

| MAX. THREAD ROLLING FORCE Kgf | 150000 |

|

|

|

|

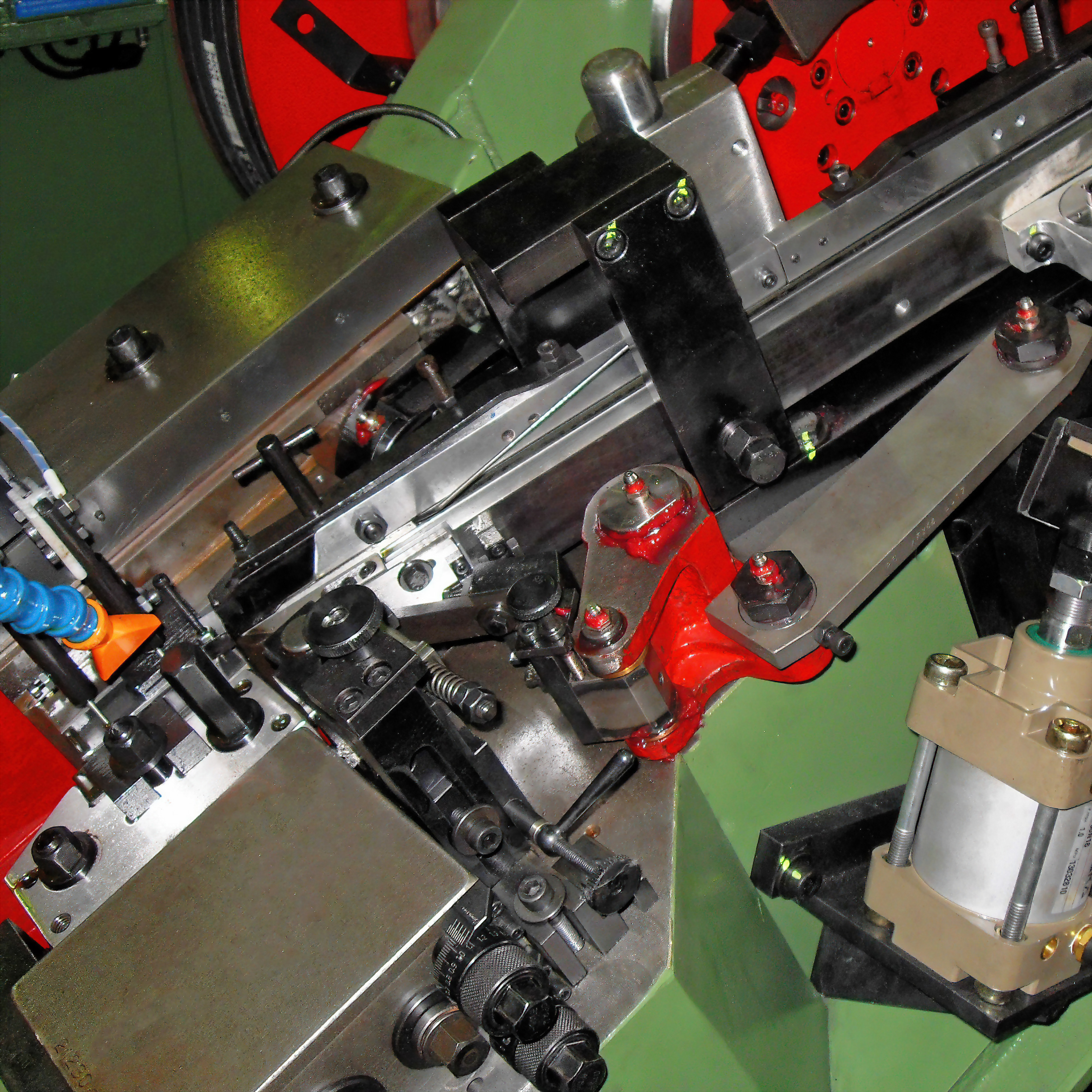

| threading zone | Blank feeding rails |

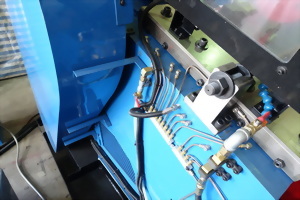

1.Lubrication system on main slider 2.Temperature sensor on main slider |

Pusher finger retractor |

|

|

|

|

| Main frame with Tie-Bar construction |

Fine adjustment die pocket |

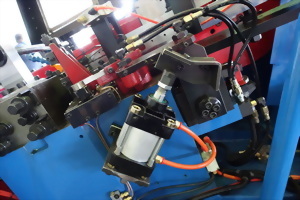

Swing type blank start system |

Sliding type blank start system |

|

|

|

|

| Auto grease device |

Sound-proof cover |

|

|